Introduction — Why Most Buyers Misinterpret SGS Reports Before DIP

In Crude Oil (BLCO, Bonny Light, Basrah, Forcados, ESPO, Arab Light…), the SGS report is the first document serious buyers need to analyze BEFORE authorizing a DIP test or Q&Q inspection.

The problem?

Most buyers:

Don’t understand the API gravity scale

Don’t know how to interpret BS&W

Don’t know what sulfur values mean

Don’t understand terminal validation

Can’t detect forged SGS documents

Misinterpret batch references and tank numbers

Cannot spot inconsistencies between SGS and pipeline movement

Fraudsters exploit this, providing fake SGS reports that look convincing but collapse under real analysis.

This guide teaches you how to read, interpret, and authenticate a real SGS Crude Oil report before scheduling a DIP test—exactly like NOCs, refineries, and institutional trading desks do.

SECTION 1 — Understanding What an SGS Crude Oil Report Really Is

1.1 SGS Q&Q = Quantity & Quality

A real SGS Crude Oil Report evaluates:

QUALITY Parameters

API Gravity

Density @ 15°C

Sulfur Content

BS&W (Basic Sediment & Water)

Pour Point / Cloud Point

Viscosity

Flash Point

Water Content

Metals / Contaminants (if required)

Asphaltenes

QUANTITY Parameters

Available volume

Ullage & tank height

Temperature

Tank reference

Batch number / Pipeline injection data

A real SGS report maps both quality and quantity based on the tank or pipeline batch.

1.2 SGS NEVER issues pre-POP or “sample” reports

SGS is an independent laboratory.

They do not:

create sample reports

issue “example SGS”

release Q&Q without inspection

send pre-verification reports for free

Any SGS sent before:

POP release

compliance

MT799/MT760 readiness

tank/pipeline access

…is fake.

1.3 SGS reports are ALWAYS linked to:

A physical tank

A specific terminal

A pipeline batch ID

A timestamp

An official SGS office

A report without these = fraud.

SECTION 2 — How to Read Each Section of an SGS Crude Oil Report (A–Z Breakdown)

Below is the institutional interpretation of every important section.

2.1 Buyer Checklist: What MUST Appear on the First Page

A genuine SGS report ALWAYS includes:

| Element | Why It Matters |

|---|---|

| SGS logo + report number | Each report is traceable |

| Terminal name & ID | Proves location of crude |

| Tank number or pipeline batch | Identifies product source |

| Date & time of inspection | Ensures recency |

| Inspector signature | Mandatory verification |

| Client name | Seller or terminal account |

| Sample reference | Links lab sample to tank/pipeline |

If ANY of these are missing → fake.

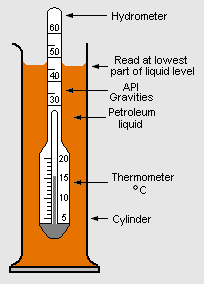

2.2 The API Gravity Section (Most Important Quality Metric)

API Gravity determines value

Light crude: > 35° API (BLCO is 33–38)

Medium crude: 22–31

Heavy crude: < 22

Institutional rule:

API must match the grade the seller claims.

Example:

If seller claims BLCO, but SGS shows 30° API, the report is invalid.

How to verify authenticity:

Compare API to density. API ↔ density must correlate scientifically.

Fake reports often have mismatching values.

2.3 Sulfur Content

Sulfur defines:

crude value

refinery compatibility

environmental compliance

BLCO typical sulfur: 0.14–0.16%

Arab Light sulfur: 1.8–2.0%

If sulfur values don’t align with the grade → fake seller.

2.4 BS&W (Basic Sediment & Water)

BS&W shows contamination.

Standard acceptable BS&W:

< 0.5% for most export crude

Anything above 1% is low-quality

High BS&W = pipeline contamination or old crude.

Fake reports often show no BS&W at all → impossible.

2.5 Pour Point, Flash Point, Viscosity

These confirm:

crude type

lifting feasibility

storage temperature

export compliance

Inconsistencies here reveal alteration or fraud.

2.6 Tank Information Section

Must include:

Tank number

Ullage

Temperature

Volume

Terminal name

Tank height

A Crude Oil tank with missing:

ullage

temperature

dip readings

…is a fake document.

2.7 Pipeline Batch Information

For pipeline-based crude:

Batch ID

Injection point

Pipeline name

Date

Volume

Terminal intake reference

Pipeline details missing = seller does NOT control any crude.

SECTION 3 — NNRV Expert Analysis: How We Authenticate an SGS Before DIP

NNRV uses a 7-step verification method:

Check report number with SGS database

Match API & density correlation (scientific validation)

Verify terminal code

Contact terminal operator (institutional access only)

Validate pipeline batch ID with government registry

Cross-check SGS inspector signature

Check consistency with typical grade characteristics

This eliminates 99% of fake SGS reports.

SECTION 4 — Step-by-Step Guide: How Buyers Should Use SGS BEFORE DIP Test

Step 1 — Request POP AFTER SWIFT readiness

Never accept SGS before MT799/MT760.

Step 2 — Verify SGS authenticity through NNRV

Document verification first.

Step 3 — Match SGS with claimed grade

API, sulfur, viscosity.

Step 4 — Check terminal & tank information

Location must be verifiable.

Step 5 — Compare SGS dates with allocation schedule

Old SGS = recycled document.

Step 6 — Only then perform DIP test

DIP test must match SGS quality parameters.

Step 7 — Confirm post-DIP analysis

SGS after DIP must align ± industry tolerance:

API variance: ± 0.3°

Sulfur variance: ± 0.05%

Large variance = fraud.

SECTION 5 — Buyer & Seller Questions (20 Professional Answers)

10 Buyer Questions

Is SGS before SPA real? → No.

Can SGS be forged? → Yes.

Who verifies SGS? → NNRV or SGS office.

What is strongest indicator of fraud? → Missing batch ID.

Should buyer pay DIP? → Yes, DIP is buyer inspection.

Can SGS be older than 30 days? → Risky.

Does SGS prove ownership? → No—proves quality only.

Should SGS include terminal location? → Mandatory.

Does SGS show allocation? → No.

Can I rely on a PDF? → Only after verification.

10 Seller Questions

When to release SGS? → After MT799 or MT760.

Does SGS protect seller? → Yes, proves quality.

Do sellers produce SGS themselves? → No—third-party only.

Should seller block DIP? → Never.

When does DIP occur? → Before loading.

Can seller reuse old SGS? → No.

Who pays Q&Q? → Buyer.

Should we allow buyer’s inspector? → Yes.

Can DIP fail? → Yes, if product degraded.

Should SGS be uploaded to a data room? → Yes.

SECTION 6 — Why SGS Compliance Is Mandatory (Legal & Institutional Framework)

The SGS Crude Oil inspection system is governed by:

API MPMS standards

ISO 3170 & ISO 3171

SGS Global Petroleum Protocols

ICC Incoterms 2020

NOC export requirements

Pipeline quality control rules

These frameworks ensure:

product integrity

terminal accountability

pipeline traceability

buyer protection

SECTION 7 — Professional CTA

📌 Need to verify an SGS Crude Oil report before DIP?

Looking to authenticate terminal, pipeline, batch ID or allocation?

NNRV Trade Partners offers:

SGS authenticity verification

Crude Oil document analysis

Pipeline & batch validation

Terminal verification

SWIFT compliance support

Complete Crude due diligence

📩 info@nnrvtradepartners.com

🌐 www.nnrvtradepartners.com

Avoid fake SGS.

Operate with institutional precision.

Mini FAQ (5 Quick Answers)

What proves a real SGS?

Valid report number, terminal code, batch ID.Is SGS alone enough to proceed?

No—you must match it with POP.Can DIP be done without SGS?

No—SGS guides DIP expectations.What variance is acceptable?

API ±0.3°, Sulfur ±0.05%.How fast can NNRV verify SGS?

12–48 hours.